John Ware, Director of Envirolyte ECA UK Ltd, details how the Envirolyte disinfection product can aid in the fight against COVID-19.

The arrival of the coronavirus created an enormous amount of interest in Envirolyte hypochlorous acid (HOCL) as a disinfection product, to see if it could be used within a wider prevention and protection strategy to help reduce the spread of COVID-19.

For years, many countries around the world have been reaping the benefits that HOCL brings to healthcare; food processing and manufacturing; water treatment; and water recycling, along with the improved hygiene standards it offers within the cleaning and housekeeping sectors. Outside the UK, the healthcare sector has used HOCL to help people breathe who have contracted COVID-19: one dying patient is reported to have recovered from pneumonia when HOCL was used to aid his breathing. HOCL is used for wound care applications like ulcerated wounds, for patients who have contracted an MRSA infection, or on diabetic skin ulcers. Wounds always heal faster when treated with HOCL, as it prevents biofilm from infecting the wound and fights off any airborne invaders that try to populate the wound.

Sadly, here in the UK we have been very slow to adopt electrolysed water technology for patient treatments or as a replacement for sodium hypochlorite (SH), which is an irritant and is corrosive, necessitating the use of PPE. SH is used for many housekeeping, clean up and disinfection applications within wards to clear up blood, faeces, or contamination incidents. HOCL is able to provide safe and superior disinfection capabilities for any tasks that SH is already used for; and can be safely used without PPE, although we recommend that nursing staff follow their hospital’s health and safety recommendations for using PPE with the individual chemical products. Anolyte ANK, our HOCL liquid, is used against COVID-19 by spraying surfaces; it can be dry fogged within occupied working environments, or even used within decontamination tunnels or chambers to disinfect people who are entering or leaving work.

Now that the WHO has finally accepted that the COVID-19 is an airborne threat, and that it is not just transmitted by droplets, our belief is that we need a long term set of protocols to ensure we have a comprehensive prevention and protection strategy in place, both at work and when using public transport like trains, buses, aeroplanes or even cruise ships. Heating, ventilation, and air conditioning (HVAC) systems in buildings will have to be adapted to ensure that COVID-19 is prevented from entering through the outside air inlet vents. It must be prevented from entering any associated office areas that are connected to air handling units (AHUs) or ventilation ductwork systems. Return air from internal spaces which is either exhausted to the outside of the building or recirculated must be prevented from allowing COVID-19 to pass back into and mix with the supply air; all the air entering a building must be treated using a method of disinfection.

There is a belief that high efficiency particulate air (HEPA) filters can be fitted to AHU systems to help remove viruses; although this might seem a good idea, AHU fans cannot always be retrofitted to overcome the resistance that the HEPA filters produce. If they were fitted, the airflow duty produced by the fan would be significantly reduced, which would in turn reduce the heating and cooling capacity that the system is designed to offer at peak winter and summer periods.

As I spent many of my younger years working within the HVAC sector, I am well aware of all the issues that must be overcome to help combat our battle against COVID-19. By implementing the use of Anolyte ANK we can help with AHU systems by fogging the supply air with our HOCL, which will provide disinfection against COVID-19 and any other airborne pathogens, bacteria or viruses that are within the airstream. Providing good quality air which is free from harmful microorganisms or viruses can only benefit the occupants within an air conditioned or ventilated building. Good quality air prevents the occurrence of ‘Sick Building Syndrome’.

During this pandemic we have been fogging, but on a smaller scale; by using desktop fogging units within workplaces, offices, schools, hairdressers and dental surgeries, to name but a few applications where people have benefited from the use of our non-toxic HOCL, which can be safely breathed in over the course of a working day. The safety our HOCL product offers can be clearly seen within our safety data sheet: it is unique when compared to the many other chemicals within the market, as the safety data will clearly show.

Envirolyte ECA UK Ltd is a BPR-compliant company that produces HOCL at 500ppm. We sell and supply the product to our sub-distributors and direct to end users, as well as offering white label products for companies.

Many of our competitors are supplying HOCL products into the marketplace at a lower ppm than ours, which is at 500 ppm. A large majority supply at 100 to 200 ppm to fight COVID-19; they also supply the dental market, but at high prices, whereas we can supply our superior product at a more competitive price and with a concentration that is 2.5 to five times the strength of theirs. A higher ppm product will allow you to use less HOCL and it will always disinfect quicker than one with a lower ppm – so why prolong the disinfection time? Reduce it by using our Envirolyte HOCL product, Anolyte ANK.

As the UK distributor, we also sell the complete range of Envirolyte machines, manufactured in Estonia: they use electrochemical activation (ECA) to generate the hypochlorous acid. This electrolysed water disinfection product has a free available chlorine (FAC) strength of 500ppm within a neutral pH range of six to seven. It is a green, safe, environmentally friendly and fully biodegradable liquid which acts as a very powerful antimicrobial and sterilising solution; and which conforms to the European Biocidal Products Regulation (BPR, Regulation (EU) No 528/2012) and is listed with the ECHA. It also holds NSF/ANSI 61 certification, which ensures that Envirolyte products meet the regulatory requirements for the US and Canada; it can often meet or fulfil testing requirements for many other countries.

The NSF/ANSI 61 testing covers all components in contact with drinking water from the source to a tap, and it has determined that no contaminants may migrate or leech from the Envirolyte product into the drinking water. It also confirms that they are below the maximum levels allowed to be considered safe. Even with this high standard of certification, here in the UK we will be submitting our products for testing to gain Water Regulations Advisory Scheme (WRAS) and Drinking Water Inspectorate (DWI) approval; we have already obtained BS EN 901 which allows our HOCL to be used for drinking water applications. Gaining UK approvals will validate further the high quality and standards of our products. The quality systems employed by Envirolyte Industries International Ltd have been certified to the international standard ISO 9001.2008.

Anolyte ANK is ideal for providing ongoing and consistent disinfection for the requirements and demands that occur within the healthcare sector. This could range from dosing potable drinking water and secondary hot water circuits; it can also be added to primary low pressure hot water (LPHW) and chilled water systems to prevent microbial induced corrosion (MIC) that is caused by biofilm buildup. It is suitable for the fogging of operating theatres or inaccessible areas, or it can be manually applied to hard or soft surfaces, which could be a part of any daily janitorial healthcare disinfection and cleaning procedure. The extensive range of Envirolyte machines can be used to serve any size of old or new hospital water systems that might have ongoing or new disinfection issues that need to be addressed.

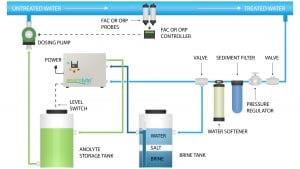

Our in situ machines are part of a bespoke system that will use one or more dosing pumps, which are operated by either a free available chlorine or oxygen reduction potential (ORP) controller and sensor for a water system at a customer’s site. The water pressure to the machine is set by a pressure-reducing valve (PRV); it then passes through a water filter and softener, before branching off into a brine tank and passing directly into the machine. The generated hypochlorous acid is stored in a suitably sized storage tank to match the customer’s requirements.

This technological process uses a mixture of ordinary tap water and a diluted saline solution, which is passed through a specially designed electrolytic cell in order to modify its functional properties without adding any other reagents. Many microorganisms develop a tolerance or resistance against conventional chemical sanitation products, which could be of concern within a healthcare environment; so it is reassuring to know that it has been repeatedly shown that microorganisms cannot build up a tolerance to the HOCL made using ECA technology, as the unique mechanism of biocidal action is distinct from that of chemical products.

Below is a typical layout for a potable water system installation.

Why use dangerous chemicals when there are safer and more environmentally friendly alternatives?

Every year people get injured or even killed due to chlorine gas-related accidents, which is mainly due to either a faulty delivery system or by having cleaning and disinfecting chemicals incorrectly mixed. Chlorine and its chemical compounds are extremely effective as disinfecting agents and the safety of our modern food and water supply chains depend heavily upon them. The difficulty has been how to maintain the safety of the food and the water supply while protecting the health and lives of those working within these areas. Using a state-of-the-art patented membrane electrolysis technology within the cell of the Envirolyte generators, they produce powerful disinfection agents for onsite usage without any risks to humans.

Our disinfection liquids are classed as non-toxic and biodegradable under EU guidelines, thus helping to protect both people and the environment; and offer the possibility of substantial cost savings, as onsite production when using our product is often substantially cheaper than using other traditional chlorine-based chemicals or products like hydrogen peroxide or chlorine dioxide systems. The liquid solutions produced by our standard range of Envirolyte generators can help to save energy and water, this is achieved by allowing some disinfection processes to be carried out at ambient or even lower temperatures. It is possible with some water processes to filter and disinfect the water so it can be recycled for wash down applications or for other processes, which is beneficial to the water circular economy. Please note that one litre of Anolyte will provide a residual dose of 0.5ppm of FAC within 1,000 litres of water in a system that is free of bacterial issues; therefore our low production price for our product makes it a very cost effective alternative compared to the other types of disinfection chemicals that are currently being used.

Our ELA ANW range of low energy and low salt machines can provide substantial cost savings over and above the economy that is already provided by our standard range of machines. The ELA ANW machines are designed to use about 1.5 grams of salt (NaCL) and 4W of energy to generate one litre of Anolyte at a strength of 500ppm of FAC. These ultra-low running costs make using this range of machines very attractive from a capital investment perspective to provide a suitable return on the investment (ROI) made by the customer.

Anolyte and catholyte: our liquid solutions

Envirolyte standard machines produce two types of fluids: Anolyte and catholyte. Anolyte is a strong oxidising solution and can be made with a pH range between 2.5 and 8.5, but for most applications we produce it within a neutral pH band of six to seven. The oxidation reduction potential is between +600 and +1200 mV. It is a highly potent bactericide that can be used as a broad spectrum germicidal agent to kill all types of microorganisms including viruses, fungi and bacteria, achieving a log8 reduction of E. coli within 10 seconds.

As a biocidal liquid, it provides the cleaning strengths and benefits of chlorine, but without any dangerous implications, therefore ensuring that there are no toxic or other side effects can harm either humans or animals. Envirolyte has developed the technology and experience required to enable Anolyte to remain stable and active in storage for up to 18 months, making it an ideal to be used as a healthcare industry cold sterilisation tool.

Catholyte is a byproduct made during the production of Anolyte on our standard machines. It is an anti-oxidising, mild alkaline solution with a pH range of 10.5 to 12.0 and an ORP of –600 to –900 mV. Catholyte solutions can potentially be used as a degreaser, detergent, cleaning aid or flocculation product. It will also remove biofilm from surfaces.

Based on extensive research, both Anolyte and catholyte solutions:

- Are environmentally friendly;

- Are non-toxic to both humans and animals;

- Do not require special handling;

- Can be safely disposed of into wastewater and sewage systems;

- Are fast-acting in eradicating microorganisms, pathogens and bacteria;

- Can be used at all stages of a disinfection and cleaning process;

- At recommended concentrations, do not bleach surfaces or materials;

- Can be applied in liquid, ice or aerosol form;

- Are hypoallergenic;

- Any byproducts are non-toxic, environmentally friendly and leave no synthetic chemical residue;

- Can be generated onsite, thus eliminating handling and storage of chemicals;

- Are produced onsite from tap water and salt in the required quantities and concentrations of active ingredients, pH and salinity; and

- Used on their own or as a combination, are effective in removing and controlling biofilm within liquids or on contact surfaces.

Anolyte applications in hospitals outside the UK include:

- Hard surface treatments;

- Handwashing;

- Instrument soaking and washing;

- Decontamination of endoscopes and washing equipment;

- Decontamination of water storage systems and associated pipework;

- Secondary disinfectant under EN15883/HTM 01;

- Podiatry – instrument washes and foot soaks;

- Radiology – wipe down of hard surfaces and decontamination of ultrasound equipment;

- Bed and wheelchair washing – Anolyte is compatible with most UK bed washers;

- Laundry pre-treatments;

- Fogging clean areas as part of deep clean or as rapid decontamination; and

- Biofilm removal and prevention techniques for endoscopes and dental equipment.

Anolyte has demonstrated for over a decade of daily use as a hard surface disinfectant that microorganisms do not develop an immunity to it over time. This makes it possible to use Envirolyte equipment in a number of areas directly related to healthcare or for maintaining the health and safety of personnel.

How Does the System Work?

At the core of Envirolyte technology are the patented diaphragmatic cells which have been designed using innovative and unique technology to effectively deliver electrolysed water solutions.

Unlike other electrolytic cells, a diaphragm separates the Anolyte and catholyte solutions that are generated respectively at the anode and cathode chambers of the cell. This prevents the two streams from mixing and interreacting to form a simple sodium hypochlorite solution, as is the case with other commercially available electrolytic cells. The invention of the double-chamber diaphragmatic electrolyser – the basic element of all Envirolyte products – marked a breakthrough in disinfection, sterilisation, and water purification technology. Similar electrolysers have been used before: EW technology was first developed in the late 1970s in conjunction with the Russian Institute for Medical and Scientific Research and earlier models of EW products were sold throughout the former Soviet Union, generally for disinfecting water and sterilisation in hospitals, which significantly decreased the rates of infections that were being encountered.

Envirolyte cells are manufactured with variable Anolyte output capacity that ranges from 20 to 6,000 litres per hour from either a single or a multiple cell configuration. Anolyte is dosed into a water system from a storage tank at a rate that will provide constant disinfection by overcoming any biological load being encountered.

The only requirements for our systems are a supply of salt, water, and electricity. The ELA range of generators are controlled by a programmable logic controller (PLC), with an easy to operate human-machine interface (HMI) which allows the end user to accurately control the pH value of the Anolyte, ensuring that the correct dosing parameters for a particular application are met.

Envirolyte has focused much of its time and energy on developing high volume systems that meet the needs of a commercial or industrial marketplace. Therefore, we have an opportunity to sell our products into these markets because our products are better suited for users who have larger volume applications. Our solutions help to meet the growing demand for safe foods and environmentally friendly non-toxic disinfectants and cleaning fluids by providing an ecologically safe alternative to toxic cleaning chemicals.

We have identified a large number of potential markets for our products within specific industry channels, but we have focused on developing and marketing all water-based applications, which include livestock; dairy production and food processing for meat and poultry; environmental remediation; and agricultural grow-out industries, as well as potable drinking and waste or sewage water disinfection. The safe food, sanitising, disinfecting, agricultural and cleaning industries are currently using products and methodologies that have become increasingly expensive environmentally, when compared against the benefits that our fluids bring to the industry.

About Anolyte and scale prevention

Anolyte ANK electrolysed water is a unique, proprietary product that represents a paradigm shift in the field of water treatment: it disrupts the organic matrix of mineral scales and other deposit constituents in water systems, unlike any other known chemical to be approved and certified by the NSF for potable water applications. As a result, the water systems that Anolyte ANK is used to treat it will rapidly become cleaner and will remain clean. This results in water that is superior in quality to water which is treated with any other conventional disinfection products. A scale free system will have lower electrical running costs for pumps and will have higher heat transfer rates within any heat exchangers or calorifiers.

Potable water systems tend to develop biofilm, which consists of a matrix of organic matter, inorganics, waterborne debris, sessile microorganisms and corrosion products adhering to metal, plastic, glass, wood, and other surfaces. Water systems also tend to develop mineral scales and other types of deposits: these mineral scale and organic deposit substrates vastly increase the available surface area or number of nucleation sites offering purchase to sessile microorganisms indigenous to water systems. Scale and deposits therefore accelerate microbial activity which aids biofilm development; this in turn increases the potential for mineral scale development and accumulation by providing an organic matrix, effectively ‘cementing’ mineral precipitates in place.

Anolyte ANK solves these integral deposit sanitation problems by preventing deposits and by making mineral scale and deposit removal fast, effective, practical, economical, non-corrosive, and non-hazardous. With Anolyte ANK there are no toxic or corrosive chemicals to purchase, transport, inventory, handle or dispose of in connection with the cleaning-sanitising process.

With continuous Anolyte ANK use, the treated water itself becomes a deposit control solution, which keeps all surfaces that come into contact with the water cleaner. Mineral scale removal with Anolyte ANK Electrolysed Water is sub-stoichiometric, meaning a relatively low concentration of Anolyte ANK is capable of removing very large amounts of deposit. It is important to differentiate Anolyte ANK from other sources of chlorine, such as stabilised bleach, calcium hypochlorite, hydantoins and other chlorine donors: its chemistry is unique; and it must be recognised that the product is very different from any other forms of chlorine.

Envirolyte truly believes that our products provide an economic and attractive alternative to other chemicals and toxic substances that are currently being used.

John Ware, AMRSPH

Director

ENVIROLYTE ECA UK LTD

john@envirolyte.co.uk

www.envirolyte.co.uk

This article is from issue 14 of Health Europa. Click here to get your free subscription today.