In this report, PURE5 discusses its innovative Pure Botanical Extraction (PBX-Standard™) method to create clean, high-quality cannabis extractions.

Pure Botanical eXtraction is the acronym for liquified gas extraction technology that behaves as CO2, leaving no residues in the final product. PBX extraction is performed under a controlled environment without access to air or other contaminants. Unlike other methods, PBX extraction process has no chemical reactions resulting in oils with no undesired by-products, without altering taste or flavour. PBX employs a non-polar media that behaves as a hydrocarbon however non-flammable and extracts only the oil without altering the remaining components that can be used in sequential processes, for example, in food or additives, supplements, and post processing.

PBX is gentle to the botanical while performing at room temperature and preserves all natural enzymes. It does not degrade the components extracted or left behind, and is so selective that it extracts only the resin compounds without the need for post processing, such as winterisation or filtration. That makes this extraction more superior than the known three major methods: by non-selective gases like CO2, chilled alcohols, and variances of hydrocarbons.

The technology has been promoted by PURE5 for over a decade and is known as a high-terpene, strain-specific, low pressure, liquified gas extraction process that is safe, automated, and precise. It has been utilised for botanical extraction of food, fragrance, and flavours, as well as for essential oils for decades.

The PURE5 Extraction Technology is guarded by at least four international patents protecting equipment and the process. The process is registered for food extraction and is GRAS (‘Generally Recognized As Safe’) by the U.S. Food and Drug Administration (FDA). PBX is a gentle process at room temperature separating the cannabinoid and terpene constituents from the raw plant material, without burning or freezing, and while still obtaining the most out of the plants. The PBX-Standard process is a game changer in the industry for simplicity, safety, and quality.

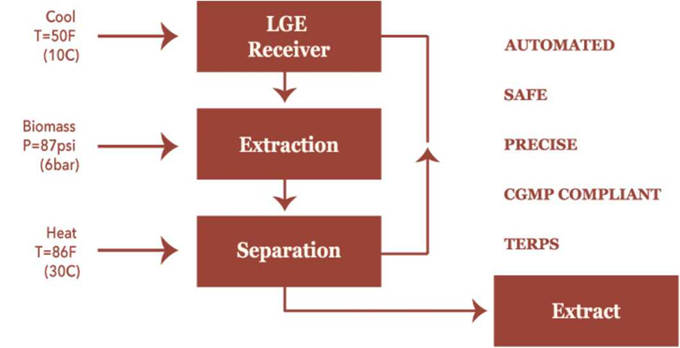

How does PBX work?

The PBX-Standard™ eXtraction technology has been developed to overcome all the disadvantages from using lower density liquified gases like CO2 for resin extraction while maintaining all the benefits of liquified gas extraction being solventless and resulting in no residuals in the extract.

It is known that the polar nature and the low density of CO2 can only extract constituents in the supercritical phase when the density allows, although in the supercritical phase it does not extract terpenes. Dropping the pressure to high sub critical pressures exploits the polar nature of CO2 allowing for limited terpene extraction. Recently the fight for the solventless nature of CO2 was lost, as most of the CO2 manufacturers officially adopted ethanol as a cosolvent.

Professionals working with CO2 know that CO2 extraction does not perform well with fresh material, as the water-gas connection brings undesired acidity levels in the resulting extract. Unlike CO2, PBX is inert, odourless, non-toxic, non-flammable, non-corrosive, and does not form acids in the presence of moisture. This broadens the scope of applications to include many pharmaceutical products that are pH sensitive. PBX-Standard eXtraction is performed at room temperature overcoming thermal degradation or loss of volatile compounds during isolation. The inherently low boiling point of the gas eliminates the need for complex and slow recovery.

PBX has been designed to exploit the natural properties of R134a (tetrafluoroethane) gas creating the perfect process where we perform, like the way CO2 gas behaves in the low sub critical mode. The small non-polar molecule size and the inert nature of the R134a gas efficiently penetrates the plant tissue thoroughly extracting the oil soluble fractions. PBX extraction is performed at room temperature and low-pressure conditions with resulting oils being seamless to the full-spectrum resin delivered from the plant.

Full-spectrum terpene profiles are collected without degradation of molecules and are easily separated from the gas. PBX is the perfect choice to extract fresh cured botanicals leaving solids (lipids and waxes) behind. R134a is hydrophobic resisting all water phase components and in most instances, winterisation may not be required.

Our machinery performs a very simple three step process that is fully automated to the operator and guarantees consistency of the product output. Load the biomass, gently soak, and wash the vital oils at room temperature and low-pressure, then gently evaporate the gas so you can collect your precious oil that can be used directly in your finished products. The entire process for extraction and separation takes approximately two hours.

We added a second input column to our systems which significantly increases throughput by minimising recovery time. Any trapped gas in the output is 100% removable from final oils without imparting flavour or tint. Traditional solvents oxidise when exposed to air, imparting flavour that is impossible to remove from your final oils.

What is the science behind PBX?

The science of extraction is very simple. Similar components extract similar components, and it is important to know the target group of compounds to be. In the cannabis flower we will be looking at quite wide group of ingredients starting from the hydrocarbons which are all mono-, sesqu-, di- terpenes, saturated, and non-saturated alcohols, saturated, unsaturated, and aromatic ketones, saturated, and unsaturated aldehydes, and ending with some saturated and unsaturated acids. In brief the terpenes, ketones, aldehydes, and acids are building the composition of the full-spectrum cannabis oil.

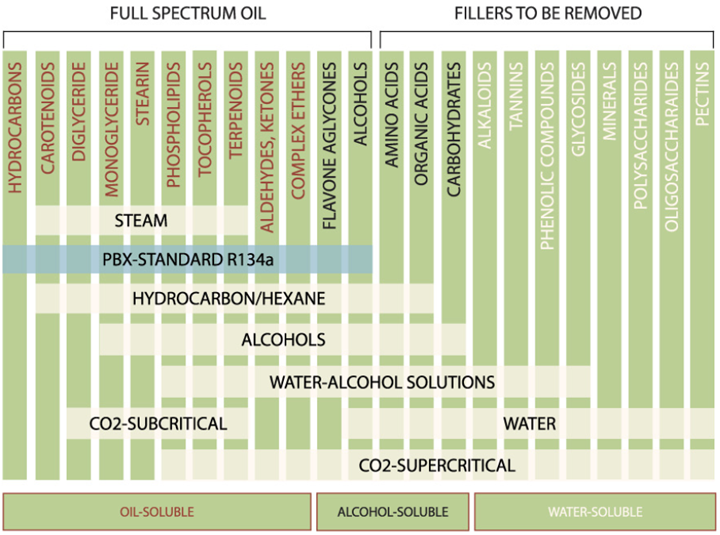

To extract the combination of those, a solvent needs to be properly selected. The botanical ingredient diagram below shows those target ingredients in red in the entire range of plant ingredients and various solvents that can extract them. There are three main groups of solvents by the target group of plant components: oils called oil solubles; the flavones; alcohols; and acids, which are known as alcohol soluble; and tannins; minerals; and pectins that are known as water soluble. That puts our solvents in three major groups mainly differentiated by their polarity.

How the polarity works

The solvents are complex organic chemicals that consist of molecules. The molecules have various shapes and special configurations which, depending on their bonding groups, may be more symmetrical or disproportional. In general, if the distribution of the electrons between bonded atoms is even, the molecule is non-polar or if it is uneven, it is polar. Polarity is a description of how different the electrical poles of a molecule are; therefore, the electrical potential of the molecule is different. So, polarity forms a scale depending on the electronegativity of each bonded atom in the molecule.

For example, the molecule of water has a large oxygen atom with atomic weight of 16 and two small hydrogen atoms with a weight of 1, and the water will have extremely polar performance as a solvent. As we see it from the chart, the water extracts polar plant ingredients located on the right side of the table. Then a hydrocarbon will have a very small inert and symmetrical bond between carbon and hydrogen, and it is a non-polar molecule that will extract the ingredients on the left side also called oils and oil soluble.

Usually, those non-polar ingredients are very volatile and have a boiling point below 20°C. Also, unfortunately due to volatility, most of those chemicals are extremely flammable. So when used as a solvent, strict safety precautions have to be considered. The next group of solvents are the alcohols, and their molecule is much more polar but still, their boiling point is below 100°C.

As we have discussed above, the electrical potential of the molecule of a solvent allows that solvent to extract different parts of the botanical ingredient table. The electrical potential of the molecule is easily characterised and measured by the dielectric constant of the chemical. To simplify the solubility of each solvent, it is enough to know its dielectric constant to have a good idea what botanical ingredients it will dissolve. For example, the dielectric constant of ethanol is 24, water is 80, hexane is two, and hydrocarbons is seven.

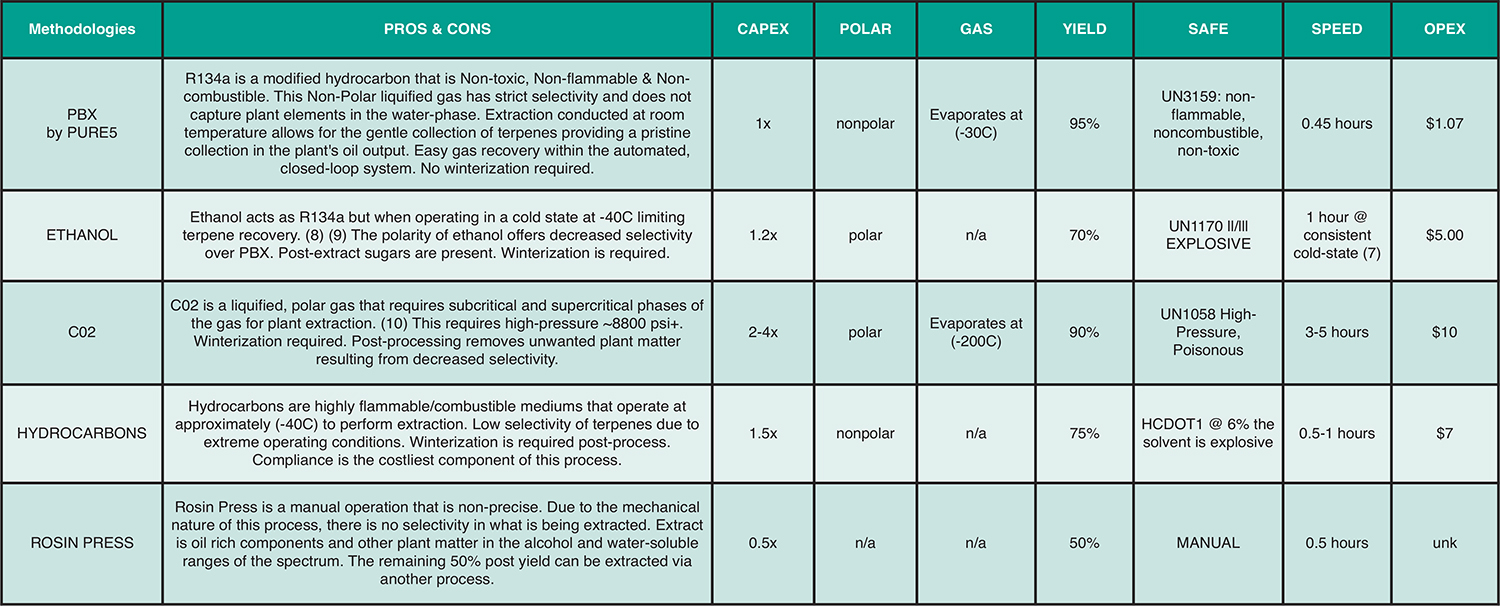

How does the PBX Compare?

Now we know everything we need to about the solvents, let us discuss the application of them and one more very important parameter – the recovery. Since the simplest extraction was making tea, the separation of the ingredients in its pure form is also very important. Once the extracted ingredients are mixed with the solvent the easiest way is to separate the solvent by evaporating it. Although evaporating the solvent will often evaporate most of our target ingredients all together, first we will have low yield of partial extract and second a contaminated solvent. What happens with ethanol, since the ethanol evaporation point is around 80C, the oils we target start evaporating at around that temperature to around 195C, so there will always be a problem with yield, contamination, and solvent residue in the final product.

That is why gas solvents as CO2 are preferred instead of liquid solvents as ethanol and highly desired in order to provide much cleaner extraction. Although a solvent extract is in contact with the plant material when in it is a liquid phase. That is why a class of extraction techniques called liquified gas extraction was developed. The idea is to pressurise or chill the gas solvent to a point that it becomes liquid and starts to behave as a solvent. Then, when the mixture of oil and solvent leaves the plant, it is easier to separate by quickly returning the gas in its natural state and the extract is drained purely without a solvent residue. That is why the CO2 extraction is called solventless.

The problem with the CO2 is that its boiling point is below -100°C and it becomes liquid at -56°C, then it becomes a more efficient solvent when its aggregate condition is beyond liquid at 31°C. That condition is called supercritical fluid, when the CO2 behaves as liquid and solid at the same time. That requires extreme pressure during the process to enter that supercritical phase. The extra energy and hardware usually make the systems built with CO2 very expensive. To simplify the extraction systems a gas with better thermodynamics needs to be selected.

For example, the hydrocarbon R134a has boiling at -30°C and being liquid at 25°C is a very sweet spot for an extraction efficiency. The R134a has the selectivity of a hydrocarbon being non-flammable extraction behaviour on a solventless process as CO2, and overcomes the disadvantages of ethanol by being separated very easily and not extracting the extra components from the right side of the chart commonly called waxes and lipids, etc.

Using ethanol, you will not need the C1D1 facility rating, but it is a class IB flammable liquid and requires meeting certain 29 CFT OSHA, NFPA 30, and IBC guidelines in order to implement it safely. Also, a handling registration from your local state liquor commission will be required. And last of the four used extraction technologies developed by PURE5 in cannabis is the modified hydrocarbon or R134a. A non-flammable, non-pressurised, and non-toxic solvent that does not require any of the above registrations and provides ready to use in products live resin and concentrate that are ready to market in 24 hours, even in their distilled form as isolated cannabis terpenes and distillates.

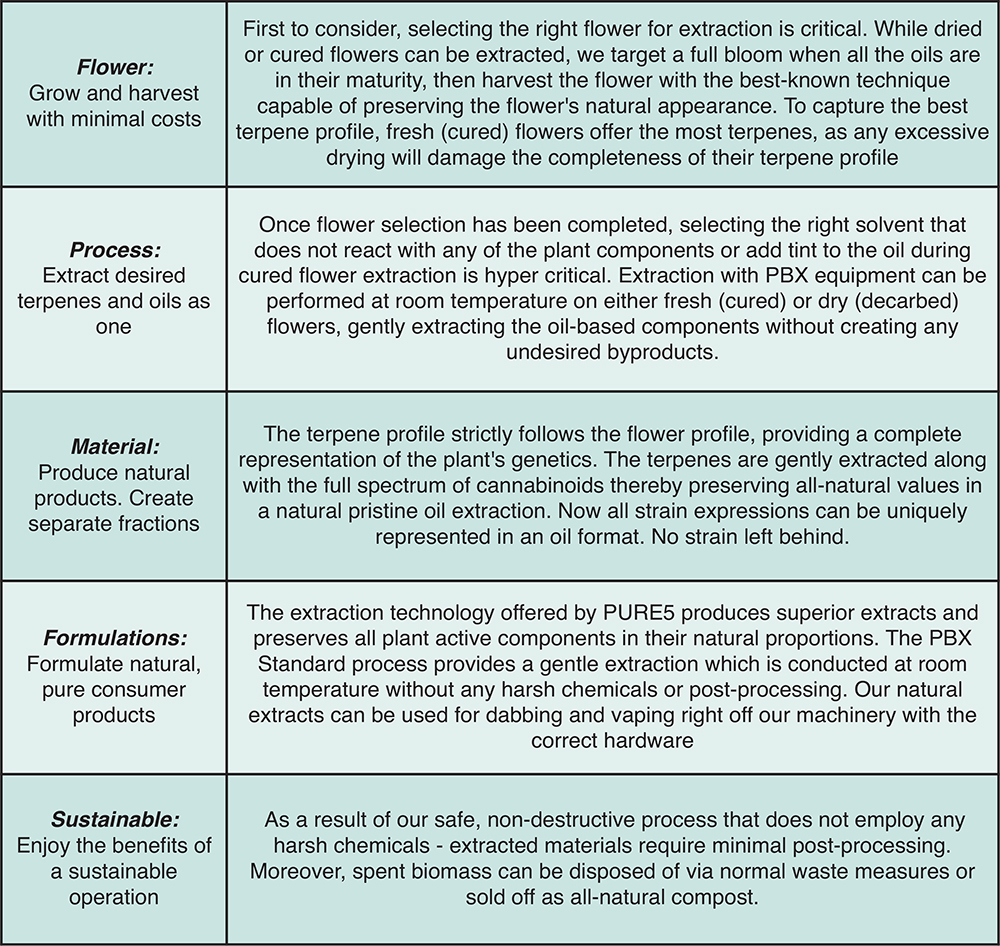

What is a sustainable product?

Utilisation of any part of the plant for the benefit of the consumer while processed with minimal energy footprint, time, and resources, while all components can return to nature is the future of sustainability.

Any business owner and processor, when considering the best extraction technology for his processing plant, must consider factors that save time, effort, and money spent to create a quality product that will put their brand on the top shelf. The raw materials are fully recyclable and do not change colour or appearance.

How to make the best PBX products?

Before starting to make infused products, we must have a good plan to avoid any further problems we run into the future. As always happens, most often we will have to start on a stringent budget. To achieve this with the quickest time to market it is best to make a kitchen with limited processing. One cannot do everything in the beginning well, so let us focus on a few core products. To make MIPs products you do not have to be an extraction expert – all that we need is to purchase raw flower biomass and make an extract.

Starting an extraction lab is a strategic business that can bring you to the market very quickly. For this, it is also very important to select the right extraction methods you and consider how that will impact your plan of action. You can always start with kief, then secure a lab to make the concentrates. However, the real infused product will like versatility. The strain specific terpenes (not botanicals), full-spectrum oil, live resin, or a distillate when no flavour are must have starting ingredients. What extraction method will give you all those ingredients while allowing for sufficient time and energy to go into the process is the right question.

There are many types of concentrates used in making infused products and every one of them is unique to the method of extraction. In its early days, the cannabis industry started with the so-called Rick Simpson oil, later known as ethanol crude, then evolved to distillates, isolates, resins, and terpenes. But even two crudes extracted from two solvents are not alike. We already explained why since the solvent will draw different plant ingredients – it is the same with distillates, distillates, isolates, resins, and terpenes.

Dabs

Dabs are concentrated doses of cannabis that are made by extracting THC and other cannabinoids using a solvent like butane or carbon dioxide, resulting in sticky oils. The dabs are made mostly from the acidic cannabinoids while maintaining high wax content. Depending on their consistency, these marijuana concentrates are also commonly referred to as wax, shatter, budder, and butane hash oil. Marijuana wax and other dabs are typically heated on a hot surface, usually a nail, and then inhaled through a dab rig. Smoking dabs as a method of consumption has been around for at least a decade, but the advent of more advanced extraction methods have led to a flood of cannabis concentrates that have boosted dabbing’s popularity.

Vapes

Vaping devices, also known as e-cigarettes, e-vaporisers, or electronic vapour delivery systems, are battery-operated devices that people use to inhale an aerosol, which typically contain cannabis oil, terpene oils, flavourings, and other chemicals. They can resemble traditional tobacco cigarettes, cigars, or pipes, or even everyday items like pens or USB memory sticks. Other devices, such as those with refillable tanks, may look different. Regardless of their design and appearance, these devices generally operate in a similar manner and are made of similar components. More than 460 different e-cigarette brands are currently on the market.

Tinctures

Tinctures are concentrated herbal extracts made by soaking the bark, berries, leaves (dried or fresh), or roots from one or more plants in alcohol or vinegar. The alcohol or vinegar pulls out the active ingredients in the plant parts, concentrating them as a liquid. There is some research and anecdotal reports that suggest some plants have medicinal properties and health benefits. Tinctures have been around for millennia and are a key component of traditional herbal medicine.

Hash

Hash comes from Hashish and is nothing more than the cannabis trichomes separated mechanically from a plant, most of the time pressed together to make a brick. The trichomes are the richest part of cannabis in plants, they are filled with the cannabinoids. The trichomes contain the most natural cannabis oil that has a wide variety of ingredients. Extracted hash is primarily used for dabbing since the oil will maintain the original plant terpenes and waxes and will bring the most natural flavour.

Rosin

Rosin refers to an extraction process that utilises a combination of heat and pressure to squeeze resinous sap nearly instantaneously from your initial starting material. The term “rosin” originated as a method of making a product used to create friction with violin bows. Depending on how it is extracted, rosin (especially flower rosin) can be considered full-spectrum. Hash rosin, however, is more commonly a select-spectrum extract.

Rosin vs. Resin

Broadly speaking, resin refers to a viscous substance derived from plants. Live resin can be made from cannabis concentrate by taking fresh cannabis and freezing it to subcritical temperatures both before and during the extraction process. This allows the live resin to retain the plant’s terpene profile, whereas with rosin, certain extraction processes may result in a loss of some terpenes. Another option of extracting high terpene resins is by using solvent hydrocarbon or R134a extraction where the terpenes are pulled from the plant with around 20 to 30% concentration and the cannabinoids with around 60 to 70%.

How to set baseline PBX production?

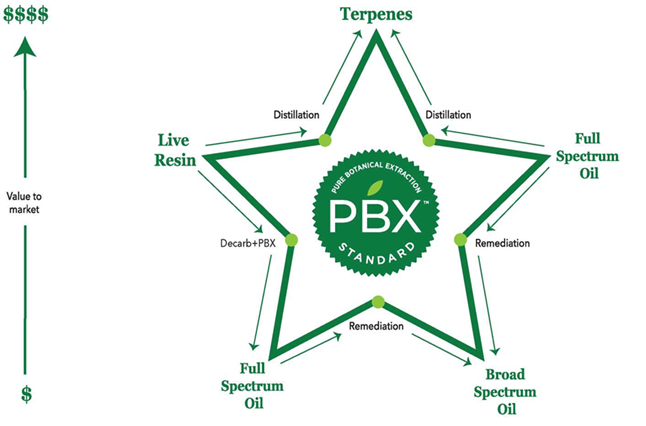

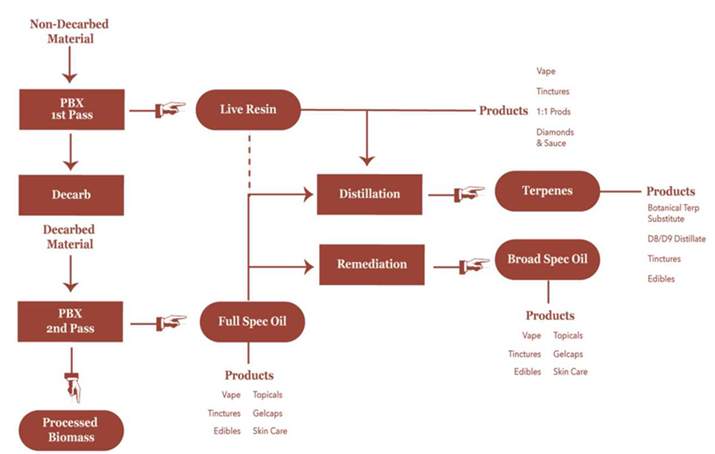

Baseline production you can start with PBX in three days. The PURE5 machines are full turnkey and delivered to spec with full SOP package as part of the PBX. One machine can slice down your plant resin in various consistencies. You can do a first slice of the live resin and second with the full-spectrum properties. You can further isolate the terpenes and make the broad-spectrum oil for hemp or distillate for cannabis.

How to scale PBX production?

When you build a lab, always be ready to scale. The hydrocarbon process due its flammability requires special C1D1 construction, licensing, and permits, and it is difficult to scale due the same reasons, however, it produces nice waxes and resins that are very much established on the market. The CO2 has been voted as a solventless method due the fact that nobody tests for the presence of CO2 in the end products and verifies the acidity level of the extracts. You will not need C1D1 rooms, but you have to provide heavy ventilation and CO2 testing since the CO2 is dangerous over 8% concentration. Although the extracts obtained have high wax content and need to go through ethanol dewaxing so both pressurised, ventilated, and controlled environments for both solvents must be met.

So, the first rule of scaling is scale safe, then scale lean, i.e., each process with minimum supporting and post-processing activities, then scale smart, i.e., expenses can always reach twice the planned amounts if not considering all details in the processing, and lastly scale with consistency, i.e., be sure everything you are manufacturing is controlled and repeatable.

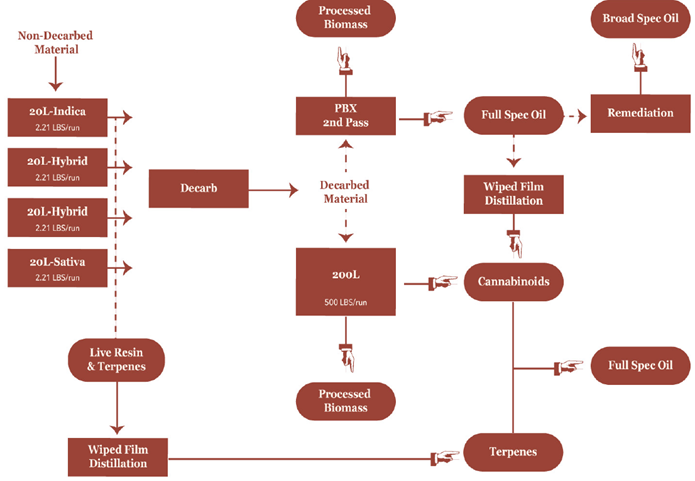

Lay out the entire process chart, stations, and people needed to support them per shift is essential. It is always best to use fully automated processes that will take care of the day’s production so your staff can complete other tasks such as packaging and QC. The chart below shows a typical PBX production flow ensuring you have proper output for the products you expect as live resin, full-/broad-spectrum oil, terpenes, distillates, and biomass.

What are the PBX production costs?

Any seasoned cannabis and hemp professional have seen all forms of extraction from the smallest and most dangerous, to the largest and highest-grade pharmaceuticals, and everything in between. One must make a clear choice to hitch best values into extraction technology in order to perform and save money. In that regards PBX is an easy choice, it literally speaks for itself.

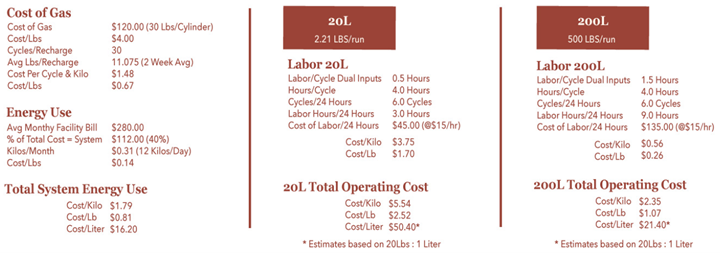

Below is a layout on the expected production costs including the gas, energy, and labour. The hard cost of operating the equipment is well below a dollar. In the case of the smallest machine, it is around 80 cent which makes it around $16/kg final extract. For operating the next 200L size equipment the cost drops down more than a half. It is around a quarter a pound or around a dollar including the labour, or around 20 kg of finished product at 20 cent a gram which ensures around 10,000 times margin of cannabis wholesale.

The PURE5 technology originates from the raw flower processing for flavour, fragrance, and food markets. We have the experience of processing over 150 herbs in various fields even for production of triglyceride oil. One can process its own bases and flavours from any botanical out there which will additionally offset the risks following the industry around the world. As part of the PBX we also offer unique recipes for end products that can be applied for multi ingredient supplements.

What is the PBX ROI?

We can share several examples why PBX by PURE5 technology is so superior across a wide spectrum of metrics where the ROI is exceptional. Let not forget that PBX is high terpene, strain specific, liquified gas extraction that is safe, automated, and repeatable, and which creates high value products. The PURE5 extraction machines are the easiest systems to operate, cleaning is easy, and maintenance is not required in a long time. PBX offers a product that is a complete flower representation in the form of full-spectrum oil and resin from which one can create superior finished products as vapes, edibles, topicals, etc.

The degree of terpene presentations is extremely high while delivering a repeatable quality and output consistency every time. The laboratory start-up investment is a fraction of the cost of its competitors and one can be in revenue in a very short period. Starting a full turnkey lab with two or three machines is unprecedented and really that is what you need to make a full range of cannabis or hemp products.

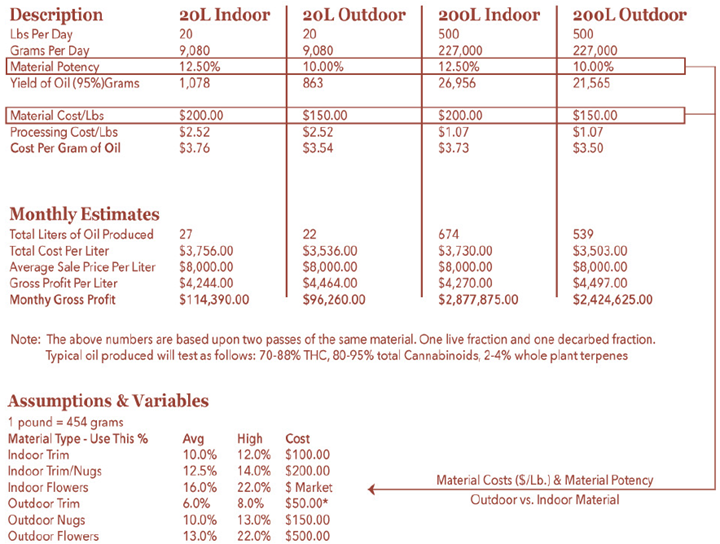

Let us look at some monthly estimates utilising the smallest two machines in cannabis with indoor and outdoor flowers in one shift. The 20L unit used in the cannabis industry is easily paid off in 30 days, and the 200L unit in half of the time. The bottom line is that with lean operation and use of high-quality indoor flowers, the ROI is less than 30 days. For the hemp industry where the sales price is around three times less it will be around 60 to 90 days for the payoff.

Can you White Label with PBX?

As a grower/processor/owner, you have to ask yourself: do I want to be like everyone else in the marketplace?

Why to be like every other product on the market with one more new brand across the shelf? Want to be different? The answer is PBX! Come and join the community where you have unlimited access to our internal resources and support that assures your success.

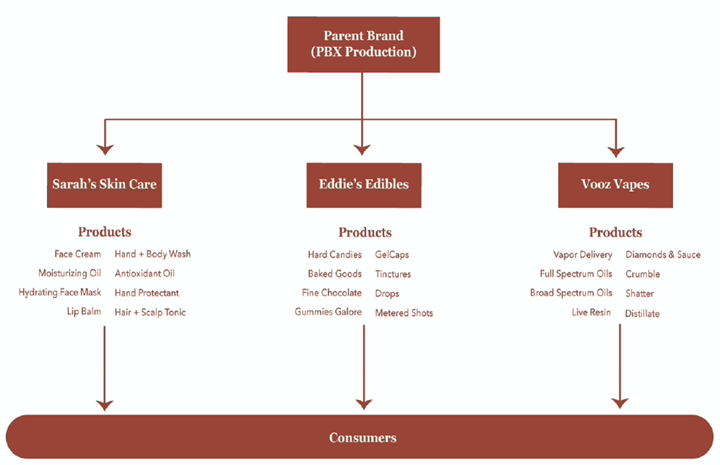

We provide you with the entire process design, SOP of extraction, product recipes, and guidance so that it can always happen the way you want it. Label design and marketing is part of the process to assure best performance on your brand. Check the below chart for three examples on three businesses involved in cosmetics, eatables, and vapes.

Here is your golden PBX opportunity!

Extracting the same old cannabis oil that saturates the market or are you ready for super power?

Welcome to PURE5 Extraction, your customers will love you for being:

- Differentiator cannabis extraction, market disruptor

- Proven over the past six years of recipe, formulation, and analytical testing data

- Over four patents and three trademarks outline the uniqueness of the process

- Pure botanical extraction gives consumers an authentically effective experience

- Immediate market demand due to growth of innovatively safe cannabis

- Environmentally and consumer safe, FDA GRAS

- Test the machine and products today, choose location Colorado, Oregon, Arizona, or California

- Join the growing community of the PBX-Standard, give yourself an industry advantage

How do you become a PBX player in your market?

- Invest in the best extraction technology on the market

- Join the PBX community and start the amazing ride together

- Come visit one of our laboratories and see how your botanical dreams will come alive

Dr George Stantchev

CEO

COMERG LLC

george@comerg.com

+1 (602) 992-0744

www.thepure5.com