Combatting floor-based transmission of infectious particles and microorganisms through the implementation of a CC Polymer Mat system, which attracts, collects and retains 99.9% of harmful particulates and contaminants from the feet or wheels of trolleys.

The world is in a very different place to where it was 18 months ago. The arrival of COVID-19 has caused massive changes – some temporary, some permanent – to people’s day-to-day lives; and no doubt it will have a lasting impact well into the future.

Prior to the onset of COVID-19, it is possible we may have taken for granted how our interactions, both casual and professional, could affect our business and personal relationships. Until 12 months ago we may not have appreciated the little things in life, like enjoying a game of football, socialising with friends or simply visiting neighbours and relatives. This also applies to our workplaces.

One positive outcome of this unfortunate scenario in which we find ourselves living is that people in general have become more aware of their surroundings and of the ways in which they need to adapt them to ensure they are working and living in the most hygienic state possible.

A significant fact of which the majority of people are unaware is that 80% of harmful particulates and contaminants enter critical areas via the feet or wheels of trolleys: the main source of contamination in a cleanroom environment is the people entering and leaving the space. A second, equally problematic source of risk is that posed by trolley wheels and truck traffic. Both activities can release particles, which will be deposited into the airstream and will settle onto surfaces depending upon air distribution – this can then lead to critical devastation in a manufacturing or laboratory environment.

This was further compounded by findings from the American Journal Of Infection Control, which cultured 120 different floors within five hospitals in Cleveland, Ohio. The results confirmed that Clostridium difficile (C. diff) spores were present on between 47% and 55% of floors, MRSA was recovered from 8% to 32% of rooms and vancomycin-resistant enterococci (VRE) were recovered from the floors of 13% to 30% of rooms.

The study concluded: ‘These results suggest that floors in hospital rooms could be an underappreciated source of dissemination of pathogens’, with investigators recommending that other modes of transmission from floors should be assessed, such as contamination of wheelchairs and wheeled equipment; and that transmission of other pathogens, such as gram-negative organisms and viruses, should be examined.

How can we combat floor-based transmission of infectious particles and microorganisms?

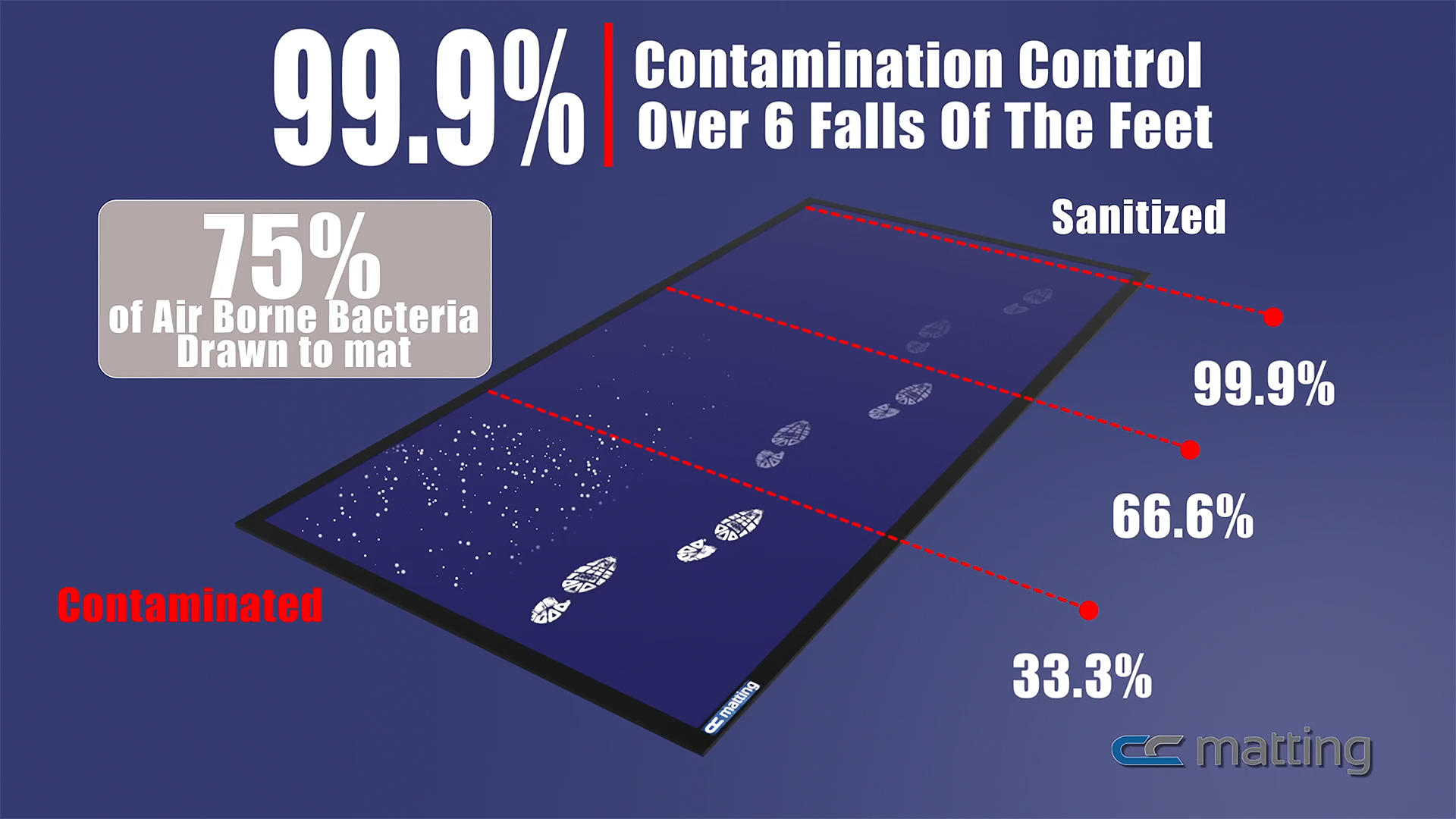

Floor-based transmission of infectious particles and microorganisms can be effectively combated through the implementation of a CC Polymer Mat system, which attracts, collects and retains 99.9% of harmful particulates and contaminants from the feet or wheels of trolleys. The high-tack layer of a CC Polymer Mat System is made of a polyester polymer with a non-migratory plasticiser on a polyester fabric backing.

The combination of the innate properties of this cocktail of materials and the sophisticated manufacturing process together create a material which has a very optically smooth, soft and supple surface with a natural tack and a high level of short-range electromagnetic forces, known as van der Waals forces.

These properties enable the surface to attract, collect and retain particles ranging in size from over 100 microns down to a few nanometres.

The particle retention capability of the CC floor mat is based on its ‘liquid smooth’ surface, which allows greater contact between the mat and the foot or wheel. The high-tack surface conforms to pressure, which allows a concentrated loading of particles. The contaminated particles remain held within the mat until the simple, efficient cleaning process is carried out, which returns the mat to its maximum operating capability.

Here we see a CC Polymer Mat System in situ in a multinational manufacturing facility. As can be seen from the image, there is a clear removal of contaminants from the soles of the feet, occasioned by the smooth soft supple surface of the mat and the van der Waals effect.

In addition to these properties, the CC Polymer Mat System contains an active silver ion-based antimicrobial agent. This is impregnated within the mat during the sophisticated manufacturing process, which leaves it non-leaching and non-diminishing. The silver biocide kills all gram-negative and gram-positive bacteria including MRSA, E. coli, salmonella, listeria and many more.

The polymer material of the mat is totally non-volatile and non-toxic which makes it completely safe for all cleanroom classifications; there is also zero outgassing which is crucial in any semiconductor environment. Further to this, CC Polymer Mat Systems boast a surface resistivity of 108 ohm, allowing them to reduce or even eliminate electrostatic discharge, which can be a major cause of concern in any manufacturing or semiconductor facility.

Going green

As well as combatting floor-based transmission of infectious particles and microorganisms, implementing a CC Polymer Mat system can help push for a greener environment. A CC Mat is 100% recyclable and comes with a life expectancy of four to five years and a full two-year warranty, thus reducing the user’s carbon footprint by comparison with shorter-lived or single-use mats – especially if a facility is using ‘tacky’, mats as these go to landfill and produce a much higher level of greenhouse gases in their production in comparison to a CC Mat.

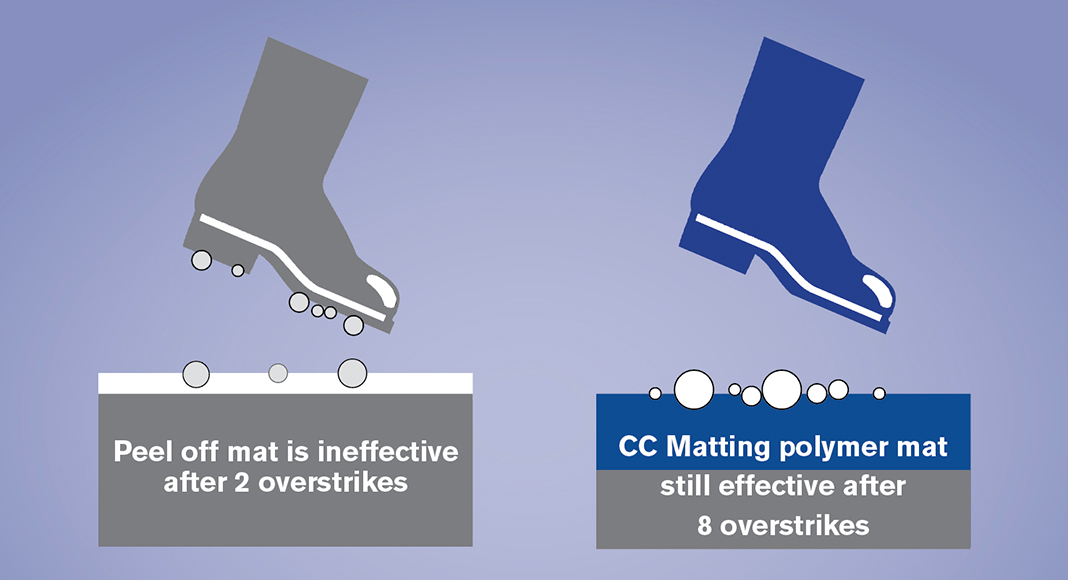

Furthermore, a CC Polymer Mat is still effective after eight overstrikes in the one spot: in contrast, a tacky mat is no longer functional after two. The levels of microbial control achieved using a polymer mat far exceed those offered by tacky mats; and there is a considerable cost saving by using a CC Polymer Mat system.

The cleaning process needed to rejuvenate a CC Polymer Mat is very simple. Simply mop the entirety of the mat with a proven disinfectant and room temperature water/or water for injection, at the ratio outlined in the manufacturer’s recommendations. This step is needed to sterilise the mat and kill any contaminants which have not been affected yet by the silver biocide.

The next step is to squeegee the mat dry: this is the most important step, as the process of squeegeeing agitates the particles which are held within the mat and brings them to the surface of the mat. These contaminated particles are then pulled from the mat with the squeegee and can be wiped clean from the floor using a lint-free cloth or similar. The mat is now returned to its maximum operating capability.

CC Matting

CC Matting was established in 2018 by Brendan and David Neary to address the contamination control needs of the life science industry. Since then, CC Matting has gone from strength to strength by winning major contracts in some of the top life science facilities in Ireland and the UK.

With the unfortunate development of the current pandemic, public awareness on the increased need for contamination control has led to many more markets being opened to CC matting. We have been selected by many schools, hospitals and nursing homes to deliver a proven line of defence.

CC Matting has thrived throughout the pandemic; and we are very pleased to have been awarded the ISO 9001:2015 accreditation. This provides CC Matting customers with a level of reassurance that our quality procedures are being maintained and assessed by a highly accredited body.

Brendan Neary-Director

CC Matting LTD

brendan@ccmatting.ie

www.ccmatting.ie

This article is from issue 16 of Health Europa. Click here to get your free subscription today