PURE5 are developing innovative, low-cost, natural and solvent free solutions to the THC remediation process.

The problem with THC

The vast majority of CBD and Hemp products currently in the market contain higher levels of THC than what is approved in the 2018 Farm Bill.

While national and international limits for THC range between 0 and 0.3%, in the vast majority of products, it is estimated to be much higher. This means there are millions of gallons of product with high amounts of THC, which poses a serious problem to the majority of distributors in the CBD market.

Being found distributing or in possession of these high THC products can result in confiscation, demand to destroy the product, fines or even incarceration.

Existing methods of THC Remediation

The process of removing or reducing the quantity of THC from products is known as THC remediation. The existing methods of THC remediation are collectively known as Chromatography. Some of the most widely used methods are Liquid Chromatography, Flash Chromatography, Reverse Chromatography and Centrifugal Partition Chromatography.

The problem with these THC remediation methods is that they use toxic solvents – such as Heptane, Pentane and Ethanol – that ruin, reduce and destroy the extract that’s being remediated and leave it with a different colour and bad odour. On top of that, these methods are extremely expensive ranging, between $0.70/gram to $2/gram and even more, the start-up cost of decent equipment starts in the hundreds of thousands, and to scale will go into the millions.

Our solution for THC Remediation

Our solution is the only solution to remediate THC through a natural, solventless and cost-efficient method. The solution is fully organic and no expertise is required to operate the equipment.

The solution is to remediate THC in a natural way, not by separating or destroying components but by converting the THC into CBD maintaining the cannabinoid potency and not harming the rest of the product. After the THC is converted, we run the oil through a distillation to complete the process.

This process would be the only NATURAL way to remediate THC without using harmful solvents. We have operational machines that can process up to 1L/day and we are currently developing machines to process 10L/day, 50L/day and 100L/day.

Our test results

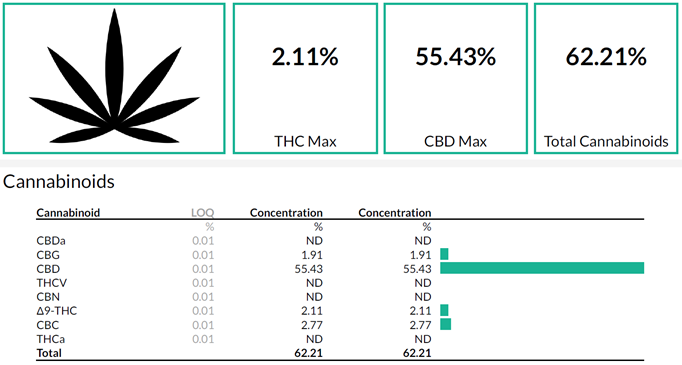

Below are example test results showing the results of the THC remediation process. Staring oil has 2.11% THC and 3 more cannabinoids CBG, CBD and CBC.

Before

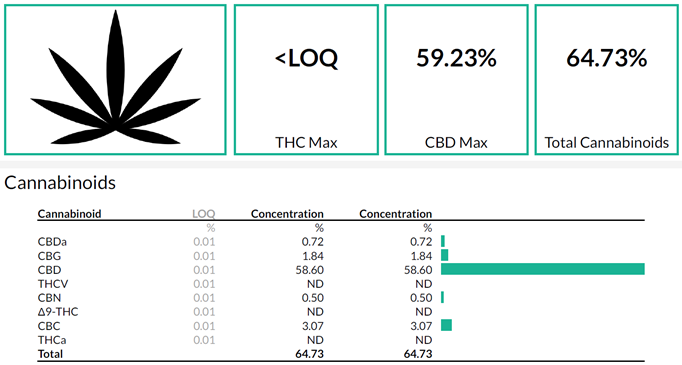

After the process is finished the entourage cannabinoids are still intact less than the THC remediated.

After

Our exceptional technologies for THC remediation and extraction are targeting solventless and fully natural process occurrence.

For enquiries please contact:

George Stantchev, PhD

COMERG LLC

+1 (602) 992-0744

www.pure5extraction.com