The experts from cannabis and hemp processing specialist PURE5 outline the benefits of its extraction and remediation technology.

THC remediation

THC remediation is the process of removing the psychoactive Tetrahydrocannabinol (THC) from hemp-derived extracts or products. To be legally compliant, CBD products must contain in general no more than 0.3% THC for the US and 0.2% for the EU, with some exceptions. For many consumers, however, the presence of any THC is unacceptable and producers in this category must achieve non-detectable, or “ND” levels of THC. Keep in mind that the allowable level of THC in the hemp plant at harvest is around 0.3% in most countries and more of the worldwide harvested hemp will exceed the 0.3% legal limit, which will convert it to 3% when extracted, it is clear that the need for THC remediation of extract and even flower is extremely necessary.

‘THC-free’ products, like Broad Spectrum Extracts, have had serious price cuts in the last couple of years, as well as many other hemp products. That is more likely caused by large-scale operations and vastly improving the operation efficiency of the process. There are a number of techniques used to reduce THC within the acceptable limits, all generally relying on various methods to degrade or separate THC molecules using chromatography, chemicals, heat, enzymes, or oxidation. Most of the involved companies are exercising their methods in complete confidence, not sharing details, raising questions of legitimacy.

Chromatography is an off-the-book process for THC remediation, mostly flash chromatography as the cheapest alternative, a process that applies pressure to speed up separation, and has high operating costs. The hard costs are in the $200-$300/ litre range, adding significant overhead to each kilogram or litre of end product. Solvents – along with ancillary recovery systems – add to costs, and labour demands can be substantial, requiring a skilled operator.

New THC remediation technology

New technology, like the wave manipulated distillation process, developed by COMERGTM and sold through PURE5TM, has the potential to change the understanding and the economics of THC remediation. Tolling fees for remediating THC in crude extract to ND levels have exceeded $1/gram, while selling price for THC-free distillate has been down to $0.60/gram, creating a need for more effective, scalable solutions for THC remediation more likely in the $0.1/gram range. That is what PURE5 provides to the customer in a complete process for remediation of flowers and extract.

Significant cost reductions

Initial investment in the chromatography technology may start from a few hundred thousand dollars, utilising Flash (FC) or Moving Bed Chromatography (MBC), to a few million dollars needed for Centrifugal Partition Chromatography (CPC). Additionally, operation costs range from a few dimes to over a dollar per gram and equipment costs of about $10,000/volume litre. In comparison, costs are just a few cents per litre utilising the low temperature remediation from PURE5 and equipment costs are around $1,000/volume litre for equipment size from 5L to 500L. That makes the process around 1000 times cheaper and equipment costs are around ten times cheaper.

Most current remediation systems have high CBD loss rates (10% to 25% of the CBD is lost during remediation), either are not scalable, have very high CapEx/OpEx, or suffer from a combination of these.

Dr George Stantchev, CEO of PURE5, said: “At PURE5, our goal is to always be on the leading edge of low-cost remediation and high-quality extraction technologies. We have been selling our IP protected high terpene cannabis extraction and utilising our know-how on THC remediation since 2015 and have further introduced a number of disruptive technologies in the world of cannabis, like the strain-specific low temperature extraction and THC isomerisation.”

Over ten years of development

PURE5 extraction and remediation achieves more than any other extraction and remediation system has been able to – offering cost-effective, very low loss-rate (<5%), organic, and scalable remediation. While it was not easy to achieve, the system that has been developed over the past ten years is ready to disrupt the industry and redefine your understanding of what is possible in isomerisation of cannabinoids. To further support product quality and safety standards, our extraction process utilises a GRAS solvent and the system is designed and built to comply with cGMP standards. Our THC remediation systems are fully organic with minimal loss of cannabinoids.

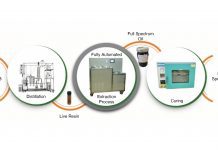

PURE5 provides first-in-class technology for turnkey extraction and THC remediation with custom in-house manufacturing to evolve constantly and develop machinery for the hemp and cannabis markets’ needs. Its patent-pending technology is a hands-free, continuous-feed, closed-loop system with no winterisation necessary, that increases the productivity, yields, and quality of each extraction at high capacity and on an industrial scale. In addition to complete systems, PURE5 offers an extraction system catalogue that includes high terpene extraction, pre and post-processing systems and supports system customers with services such as installation, site review, field verification, permitting, operation and more.