Introducing Quantum Hydroponics Services: Director Barry Winsbury takes us through how Quantum can help your plants to thrive.

Quantum development was founded in 1983 after reading about and experiencing phytophthora and root rot first hand, in both Nutrient Film Technique (NFT) and ebb and flow systems that I had built myself. I had long been pondering to myself and expressing to others that there must be a better way after watching UK hydroponic system manufacturers over the years changing system designs to try and get around the problems; not only with root rot but other complications such as bugs and fungus gnats.

The Quantum solution

Quantum hydroponics growing equipment is the only system specifically designed with cannabis and intense commercial farming in mind. Larger establishments may wish to plant and grow more than one container, whereas smaller farms may like to use a ten-week cycle providing regular weekly harvests. For example, a 1 x 20-foot container holds 65 Quantum units, each holding 50 plants and therefore servicing a total of 3250 plants.

If this is split into ten runs – five runs of six units and five of seven units for example, planting one run each week until full and then harvesting and replanting the first run – then this method provides 51 plus harvests annually. Quantum units are rated at 2-4 kilos pending lighting and plant genus and at 50% capability 12-14 kilos per week dried flowers and root harvest 3/5 kilos dried.

Faster plant turnaround

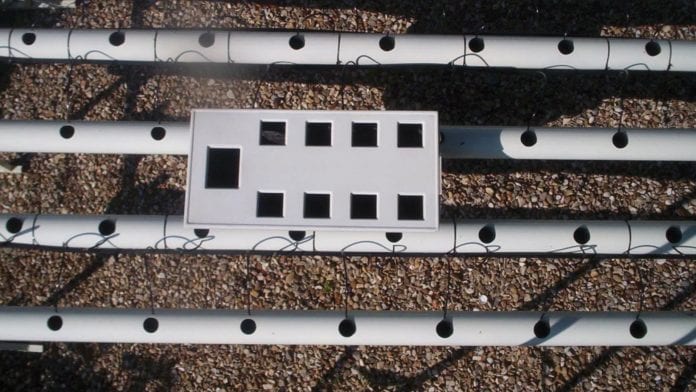

Come harvest time all that is required is to simply lift the plants and cut away the net pots leaving the root in tubes, remove the end caps, pull roots out place in wheelbarrow, replace the end caps and with a quick flush Quantum is ready for replanting. Plants live and grow in 50mm net pots and although this may sound small, a 6-foot finished plant can live comfortably in them.

By using nutrient dosing equipment plus electrical conductivity (EC) and pH monitoring equipment, Quantum becomes simple growing by numbers; the need for a grow master is gone and your budtenders become your eyes on the plants. With your budtenders watching over the plants, its leaves provide a first line of defence. If they are alert and searching for light, then all is well; however, if they are bowed and sagging then there is a problem and the remedy is to change the nutrient.

Even if your meters are telling you there is no problem, change the nutrient and get the meters checked – your plants do not lie. Today’s technology can be linked to a mobile phone with an immediate alarm is raised once the set parameters have been exceeded as a reliable second line of defence. Water pumps are very reliable and again, today’s technology allows flow meters to keep checking that your pumps are working.

Creating Quantum

In the process of creating Quantum I did at one point consider Deep Water Culture (DWC), but I later decided against the idea due to the amount of nutrients involved and the difficulty in linking the systems. Still requiring a fuss free commercial system, the experimentation went on using an array of different troughs and buckets, but success was still elusive. Eventually one day while talking with friends, the hanging gardens of Babylon came up in conversation and my thoughts drifted back to studying history at school and pictures of terraced gardens along the Nile. The penny dropped with Nutrient Trickling Technique (NTT). The architect probably never thought of it that way – he was just building an impressive display.

The hanging gardens of Babylon were built with clay blocks and bricks, with water pumped up and running over the staircase of clay, trickling over and around the roots. No soil was involved and over time there may have been a layer of leaf mulch, effectively shading the root structures. Clay being virgin soil is full of micronutrients and the water eroded the clay whist at the same time feeding the plants. The hanging gardens of Babylon was fabled to grow large plants and the fact is it did, probably huge ones. Nutrient trickling technique creates static electricity which in turn creates a turbo effect on the plant, allowing the uptake of nutrients and liquid for growth to be accelerated.

Did that knowledge originate from the stars as a lot of ancient knowledge is thought to be? From researching and reading articles found online relating to static electricity being created by water pumped at pressure via a plastic pipe, along with reading other articles showing that electrically charging plants results in considerable improvements compared to plants which are not charged. This led me to continue experimenting with the Quantum system and carrying out some tests.

Impressive results

I took two eight plant herb units one of which had plants smaller than the other. The larger plants were supplied a pump with a timer of 12 hours on and 12 hours off for five days and when the smaller plants reached a similar size the pumps were switched back on. The smaller plants were a little behind at first but by harvest time the smaller plants became larger. The experiment has been repeated with similar outcomes, confirming the theory of static being a turbo charger.

Furthermore, static electricity and NTT eradicates Root rot. Could this be because of the qualities of water? This article (https://skullsinthestars.com/2011/05/27/water-has-properties-that-are-positively-electrifying/) is very interesting reading if you are that way inclined.

Showcasing my creation using herbs the unit entered the National Gardening Awards in association with UK Style TV at Olympia, one of London’s premier exhibition centres and scooping two awards for the best environmental conservation or wildlife product and best garden machinery or equipment. The judges were amazed at the individuality which originated from 8 different varieties all living in the same environment. Not having the good fortune to be herb farmer living in London, along with restrictions in the UK and not knowing the right people to explore Quantum’s applications for growing cannabis, I decided to shelve the project in 2007 and wait for a more favourable time.

In December 2018 I discovered LinkedIn and the Legal Cannabis Group leading to the rebirth of the project. I decided to build a vacuum forming machine assuming that the troughs would be perfect, although I got a rude awakening. Going back to the drawing board and after some brainstorming, I eventually settled on using four-inch pipes. Firstly, it was two tubes with a stand, one end feeding into a nutrient tank and the other holding ten plants.

This was presented to a few people but never gained any traction until I discovered commercial farms which was truly a Eureka moment. This tube idea evolved into longer tubes feeding out of both sides of the tank. No reputable commercial farm cannot have hundreds of tanks to top.

I don’t recall now exactly what tipped the balance – I suspect it was rolling tables – but suddenly there was a manifold of tee pieces making a table with tubes attached. Being a hands-on innovator, I went back to work, drilling and sawing a few hours later and Quantum’s 50-plant system was soon a reality. Not only that, it is linkable, with no inherent problems and a fuss free performance with feed and return pipework linking back to nutrient tanks. Supplied with three stands for each unit ensuring a sturdy platform for the system to rest on and made of aluminium it is easily adaptable to implement a support framework for plants and lights if needed. Quantum is free from stands for vertical stacking; the wheeled racking that is currently being used in the industry would suit quite well. Pumps and tanks have not been implemented as of yet due to varying run sizes, volumetric loading plus local availability.

Savings compared to soil

Utilising a 20-foot container servicing 3250 plants and 3250 soil planted plants to replant 3250 using soil uses approximately 1100 bags of soil. At £10 per bag (~€11) that equates to £11,000 plus labour emptying, refilling and recycling around 3.5 tonnes of soil and root matter. As some bags of soil cost closer to £20 or £30 per bag costs could run much higher. Landfills paid for by specialist waste companies now operate in the USA equating to around 15-18 tonnes of waste to be paid for annually. Paying for soil and for disposal increases the pence per gram considerably.

Conversely, replanting 3250 plants using the Quantum system (if all net pots are unusable) is around £135.00, with only a bag of net pots to recycle. Using a low-grade soil virtually pays the free on board (FOB) price of a Quantum 20-foot farm in a box and using a top-grade soil pays for a Quantum system, installation and possibly some change in your pocket. With estimations that 95% of Europe’s cannabis is being indoor and hydroponically grown, a zero-waste system ensures licensing compliance for the future. Quantum, with its unbeatable standard operating procedure used in conjunction with reverse osmosis technology provides zero waste expectancy.

Soon to come – Quantum’s vegetetor

We are currently developing a 50-plant unit for propagating a vegging room – a unit on wheels suitably spaced for the plants to be able to reach 14-18 inches. When the time comes to transplant, simply unplug the vegatator and wheel it to the flower room – one unit will take approximately 20-30 minutes to replant. In using the Quantum vegetator, no light time is lost in the flower room and plants can be put into flower the same day as no root shock occurs. Farm in a box users will soon be able to benefit from this technology which will be made to order for the time being.

Growing for seed

Seeds have been grown with the Quantum system considerably larger than their soil grown counterparts and it is possible to cross many different seeds from the same plant using a paper bag to pollinate. It is straightforward to regulate how many and what varieties of seeds are required and germination of these seeds is faster with a higher volume and percentage of good seeds from pollination.

Higher tolerances

With plants requiring around a litre of water a day each, they have a higher tolerance to heat while remaining able to produce bud withstanding a far higher temperature than soil grown plants.

With minimal fluctuations of of EC and pH, nutrients maintain a long lifespan between changes. It is possible to follow the nutrient manufacturer’s directions on the bottle using no meters and no pH monitoring – simply watch the plants and their water levels, as soon as its water uptake is seen to slow down, change it and still get great results.

Factory rules and regulations

When setting out Quantum’s layout adjoining pipework is made to allow wheelchair access. In the wheelchair it is still possible to reach the centre tube and work with others. Quantum reaches the standards of laboratories with the most stringent guidelines.

Barry Winsbury

Director

Quantum Flowers Ltd

+44 (0)1945 466193

barry@quantumhydroponicservices.net

www.quantumhydroponicservices.net/

This article has also appeared in Health Europa Quarterly Issue 11, which is available to read now.

Barry, do you have more pics? Please send to smartnute at gmail. Thanks, Lee Roberts