PURE5 Extraction comprehensively analyses the pros and cons regarding hash rosin and the company’s groundbreaking Hash Resin™ product offering.

In the hunt for the best customer experience, the cannabis industry went through a full circle, from flower production through concentrates extracted in various ways all the way back to solventless extraction. A lot of terms were used in this quest in the game for winning customers, like Rick Simpson Oil, Clear, Shatter, Crumble, Batter, Hash Resin, Live Resin, Live Rosin, etc. What is the right game and the truth behind all marketing terms?

What is rosin?

By definition, rosin is a cannabis extract made using heat and pressure. The cannabis plant material is placed in a press with heated pads and then compressed, squeezing out hot oil. The process is solventless, so no solvents or chemicals are used in creating rosin, rather than a lot of heat. This process was originally used to create rosin for violin bows, which is how the concentrate gets its name. Rosin is a waxy product considered to be consumed in a dab rig. However, it can also be put in a cartridge and vaped.

Types of rosins

Different types of rosin include:

- Flower Rosin—uses dried nugs, mids, shake or trim; most common source material for rosin, and more flavourful than hash rosin;

- Live Rosin—uses frozen weed plants; more flavorful than other rosins as using frozen plants preserves terpenes and flavours; and

- Hash Rosin—uses bubble hash or dry sift hash; generally harsher than flower rosin as hash is harsher, and can be more potent depending on the hash used.

Hash rosin benefits

Simple Extraction Process

Compared to some other extraction processes in the cannabis industry, hash rosin is fairly simple to make. Unlike some forms of hash making, rosin doesn’t rely on special hardware, so it can be made both at home and in a commercial environment. All you need to have is a hot iron or hair press, some parchment paper, and apply a lot of pressure.

Hash rosin drawbacks

Residue

If you choose to dab the rosin or even smoke it through a vaporiser device, you may quickly find large amounts of residue. Due to the high lipid counts in some rosin products, a gunky residue can be produced, which isn’t very pleasant to smoke. Depending if you use dry or wet plants directly, you may end up with chlorophyll and plant particles that significantly alter the taste.

What is Hash Resin™?

Hash Resin™ is a trademark of PURE5™ Extraction and is created from dry or wet plants run through a closed loop system circulating a safe aerosol gas. The process is gentle to the flower while preserving its natural appearance. Our process is performed at room temperature in an airless environment, therefore, there is no oxidation preserving the terpenes and the cannabinoids in their unaltered form.

Types of Hash Resin™

Different types of hash resin include:

- Live Resin—uses fresh nugs, mids, shake or trim;

- Terpene Rich Resin—uses dry uncured nugs, mids, shake or trim run at low temperature; and

- Full Spectrum Resin—uses dry cured nugs, mids, shake or trim;

Hash Resin™ benefits

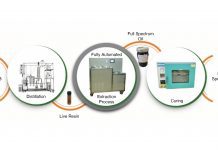

Fast Process

Even though it requires a machine to perform the process, it is fairly simple. The process is fully automated and extraction can be performed within 15 – 60 minutes. The flower is introduced in a vessel and the extract is collected from the collector. That is all an extractor does to obtain Hash Resin™.

Elevated Experience

Due to the unique selectivity of the aerosol, there are no waxes and lipids in the extract. Therefore the extract has a high potency of the cannabinoids as it is not diluted in unwanted compounds. This results in an extremely potent strain-specific experience rich in natural terpenes and cannabinoids.

Excellent Taste

As aerosol extraction is used in the flavouring industry, the taste is absolutely stunning and natural. There is no aftertaste as experienced from butane, ethanol, or CO2 oxidation. From waxy rosin press or CO2 a bitter plant taste is expressed.

Low Cost

Since the aerosol is a gas, there is no loss in the process due to the full recovery. The energy used for the extraction is minimal as no excess cooling or heating is required to maintain a very low operating cost. Practically pennies a gram for the extracted oil, so the cost of the material drives the cost of the extract.

Hash Resin™ drawbacks

Initial Cost

As the method requires customised equipment, there is an initial capital cost involved. The cost of ownership is much less than other closed-loop systems, as the minimal operating costs allow you to recoup your investment significantly faster.

Rosin vs Resin: What’s the difference?

Many confuse ‘rosin’ and ‘resin’ because the two terms sound so similar. Broadly speaking, resin is the sticky substance secreted by trichomes on marijuana plants. Chemists call it oleo-resin since it is a tick oil substance. Rosin is extracted through heat and pressure without any chemicals. Both resin and rosin are made from either wet or dried cannabis material. These extracts can be complicated further with the terms ‘live resin’ and ‘live rosin’ as we have explained above.

The process of making rosin is typically more labour-intensive and costly, so rosins tend to be more expensive than resins. Because rosins are claimed to be solventless, they are thought to be cleaner because they don’t use chemicals such as butane or ethanol. Although the aerosol Hash Resin™ fully resolves the cost, taste and appearance of a product and takes a significantly higher place in providing a better experience.

As resins require solvents and a closed-loop system, they should only be created by licensed professionals in a certified lab and only bought in a legal market that requires products to be tested. Below is a simple comparison between the hash rosin and Hash Resin™ processes.

| Description | Live Hash Rosin | Live Hash Resin™ |

| Process | 3-step process:

– Water ice wash – Filtering kief – Pressing the kief |

1-step process

– Extraction |

| Timing | 30min ice water wash

30min Filtering 30min Pressing |

15-60 min Extraction |

| Yield Efficiency | 10% | 30% |

| Startup Material | High-quality flower | Any grade flower |

| Processing | Manual Process | Automated Process |

| Capital Cost | $25k Cold Water Bath

$10k Filter $15k Press |

$125k LPE Extractor |

| Processing Cost | TBD | 1 cent/gram |

| Volume Processing | 2-3 lb/h | 2-3 lb/h |

| Description | Hash Rosin | Hash Resin™ |

| Process | 2 step process:

– Sifting kief – Pressing the Kief |

2 step process

– Decarboxylating – Extracting |

| Timing | 60min Sifting

60min Pressing |

60 min Decarboxylating

60 min Extracting the |

| Yield Efficiency | 56% | 96% |

| Startup Material | High quality flower | Any grade flower |

| Processing | Manual Process | Automated Process |

| Capital Cost | $25k Sifter

$15k Press |

$5k Decarb oven

$125k LPE Extractor |

| Processing Cost | TBD | 1 cent/gram |

| Volume Processing | 2-3 lb/h | 2-3 lb/h |

PURE5™ technologies provide an unparalleled customer experience

To provide an elevated customer experience and vital health through innovative natural processes, our products at PURE5™ have been developing state-of-the-art technologies. We look at plant processing as gourmet cooking. We provide you with the tools to formulate the best-tasting products and a fulfilling experience. We did an overview of the hottest customer product – Live Rosin and Hash Rosin and what alternatives are available for the customers that provide a better experience. PURE5 Hash Resin™ is an outstanding achievement in the breakthrough of the latest technology and science.