Pure5 Extraction guide us through the solvent extraction process used in the production of medicinal cannabis.

In order to understand the production of concentrates, one should understand the principles of the numerous extraction processes, as well as understand post-processing and the standards of making concentrated products. Traditionally working for a solvent extraction lab or manufacturer has been the only way to learn, and even then, practical experience isn’t always assured. In this article, we will provide you with information that is usually kept behind the scenes.

What is Solvent Extraction?

Cannabis oils are extracted from fresh, frozen, dried material and cured flowers using a variety of solvents. In a solvent extraction lab, CO2, ethanol, butane, and propane are the most often encountered solvents. We will discuss what you need to know in order to select the right method, by enabling you to recognise extraction efficiency, quality and speed, as well as understanding equipment safety.

There are two main types of solvent extraction: ambient and liquified gas. Ambient extractions have been used for centuries, originating back in Roman times and the famous Roman scientist Aelius Galenus. Galenus introduced typical water and ethanol extraction, as well other solvent extraction methods, which he used to formulate over 150 remedies.

Novel extraction methods include the use of so called liquified gas extractions, such as CO2 and hydrocarbons. In this process, newly developed gasses are used to extract and provide pure ingredients without solvent residues. Liquefied gas extractions are a faster and cleaner way to obtain vital plant ingredients in medicinal concentrated form.

What is Solventless Extraction?

Heat, pressure, and agitation are typical solventless extraction techniques which are used to remove cannabis trichomes first, and then the resin from the plant matter. These techniques are considered to be the safest forms of extraction as there is no chance of leftover solvents in the finished product. Since solventless extractions are purely mechanical, there is no selectivity in the obtained extract and the product almost always needs to be purified before it is offered to a customer or incorporated into a product.

The most popular ‘solventless’ extraction method is called bubble hash extraction. Bubble hash is a concentrate that is extracted using ice water. Millions of trichome glands, that resemble granular brown sugar, make up the bubble hash, which when squeezed together looks like a traditional hash. Since there is no selectivity of the ingredients, the bubble hash resembles a conglomerate of wax, cannabinoids and terpenes, with small amounts of chlorophyll, that need to be further refined before they are offered to the customer.

The next step is pressing the hash under a high temperature in order to melt the volatile compounds and separate the oil form of the cannabinoids. The high temperature converts the cannabinoids, causing them to lose most of the terpenes while keeping all the waxy content produced by the trichomes from entering the extract. Usually, the press is not able to deliver the sufficient high-quality raw material needed to formulate products.

Between 5-20% of the waxy content finds its way into the resin, meaning further processing is required. As a third step, the extract needs to be winterised in order to obtain a commercially viable form. Once it has been winterised, The remaining terpene content gets lost and the entire solventless concept becomes obsolete.

What is post-processing?

Post-processing is essential in all solvent-based extraction methods, as well as some forms of solventless extraction. Post-processing, regardless of the extraction technique, is what distinguishes many cannabis products, including wax, shatter, budder, distillate, isolate, and more. Typical forms of post-processing are winterisation, filtration, distillation, chromatography and remediation. Usually, each one of these requires separate machinery, even though some vendors may recommend otherwise.

In order to estimate what type and how much post-processing you need, you need to know your prior process in detail. Selectivity is a limiting factor in this process. The main plant ingredients in post-processing are either oil-based, water-based or acid-based and each process uses various mixtures of those. That is why selectivity is important, as it is a key in the delivery of the pure natural ingredients used in the final formulations.

Each solvent has a specific selectivity that needs to be taken into consideration, for example, oils will extract oils, ethanol, will extract acids and water will extract water-based compounds. That is why post-processing is almost always a solvent process, with the exclusion of distillation, where the separation occurs based on a boiling point temperature.

What are Residual Solvents?

The residual solvents in any concentrated product are one of the most critical areas to evaluate when identifying the safety of the product. Once the extract goes through the solvent extraction process and post-processing, this solvent needs to be removed completely, as there are critical regulations around residues in the final product.

This battle is easily won by using liquified gas extraction methods as the gas is easily introduced and removed from the concentrate without leaving a residue. Although even in that case one needs to be aware of the aggressive nature of the gas used as some gasses easily create by-products in the final extracts. For example, the highly oxidative CO2 creates undesired acids, and butane hydrogenates the oils and creates undesired aftertaste.

What is important to consider in this case, is that the use of extremely inert gasses with low miscibility in oils and water does not alter the natural organic plant molecules and is not present in the final product. These compounds are difficult to come by, but they are used in extraction. For example, PURE5 was developed as an extremely novel extraction and purification method, utilising aerosols that are extremely safe and inert gasses used for drug delivery.

What are Terpenes and how are they affected during extraction?

Terpenes are aroma compounds that play a crucial role in the experience someone has when consuming a concentrated product. The terpenes are volatile substances that are mainly concentrated in flowers. They emit fragrance even at ambient temperature, which makes them difficult to capture. They are best obtained from fresh plants as a substantial part of the terpene is lost in the drying process.

There are over 3,000 terpenes known in nature. Some cannabinoids are considered terpenes as their structure contains a base carbon ring with a terpene tail. This is why extracting cannabinoids and terpenes as a whole is the best way to preserve the natural plant potency and medicinal effect. However, only a few extraction methods can really preserve those all together, and even fewer can preserve them during the post-processing.

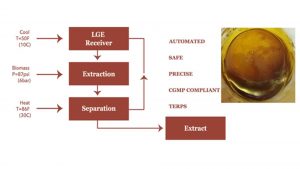

In an effort to preserve the botanical vitality and consistency of the plant resin, PURE5 introduced a novel liquified gas extraction and post-processing method that can preserve the original terpene and cannabinoid profile without extracting the fillers in the plant, which have no direct value in the final product. The process is performed at room temperature, which allows the process to be carried out without stressing any of the precious oils in the mix.

What is Chromatography?

Chromatography is a process in which a natural extraction is fractionated into individual or specifically grouped compounds. We are one of the leaders in the terpene extraction industry when it comes to fractioning cannabis oil.

Chromatography is often used in chemistry when one or more solvents with different selectivity are used to separate the main compounds in the plant extract. This is usually done with a column. The extract is passed through the collum and diluted with a solvent which activates the column. After the extract passes through the column, the solvent should be removed with no residue, which requires another piece of machinery.

Our view on chromatography is that this process is not essential if you plan your process to be selective from the beginning, and your resin remains in a pure form, even after extraction. The selectivity of the aerosol gas PURE5 utilises is extremely selective toward the terpene-cannabinoid mixture and is unselective toward the acid and water-based compounds that are not in the target mixture.

What are the Concentrates?

The majority of cannabis flowers available in the US average around 15-25% THC. However, concentrates after extraction average around 60-70% and the market is looking for concentrates between 60-99%. To achieve this, there is a process of concentration, but we also need to be conscious that when a product is concentrated, some compounds increase significantly, while others are removed.

There are also chemical and solventless methods of concentration. For example, solvents that are selective toward the filler compounds are used when producing isolates, but these are not selective toward the main ingredient. To make a CBD isolate hexane or pentane is used as they do not dilute the CBD but instead dilute the other compounds. The process is usually lengthy as it goes through multiple phases of concentration.

At PURE5, we believe that sufficient concentration can be achieved by solventless, low-temperature distillation and natural crystallisation of compounds, rather than utilising aggressive solvents in the isolation of cannabinoids. In the same way, one can achieve 100% concentration of the terpenes without the need for a solvent process that usually decreases the yield in time.

Aerosol Extraction Lab

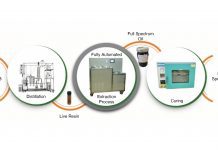

The PURE5 process is simple and for the lab usually, one piece of fully automated equipment is enough unless you need to produce concentrates. A safe GRAS gas is run in liquid form at room temperature through the biomass. Within 15-60 minutes, you can obtain a pristine natural extract that is a complete mixture of terpenes and cannabinoids. It is the purest form of natural extract, its form is exactly as appears in the plant with preserved vitality and enzymatic content.

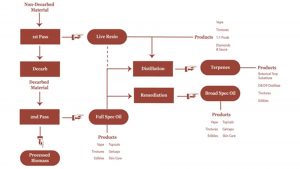

With PURE5, the postprocessing involves a simple separation of cannabinoids and terpenes by cycle, time or temperature without the use of reactive solvents that change the consistency of the oils. You can create live resin, full-spectrum oil, distillate, crystals or pure concentrated terpenes. Even our remediation equipment works without solvents and uses natural conversion between the cannabinoids.

In conclusion, we believe the word ‘solventless’ is another overstated term that applies to the initial process but not necessarily to the product the customer gets. At PURE5, we value the customer experience and created a process to preserve naturality with high confidence. It important for us is to deliver a purely natural experience to the customer without altering the taste or strain consistency through chemicals and heat. We treat nature gently in order to draw the most benefits from the gifts we receive from the botanicals.