In this article, Ypsomed, discusses how the adoption of prefilled self-injection systems has put the drug delivery device industry at the forefront of the global plastics challenge, using YpsoMate Zero – Ypsomed’s net-zero carbon emission prefilled autoinjector – as a case study.

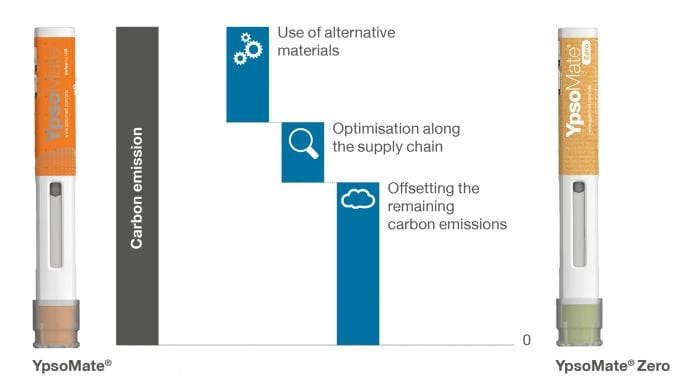

This article explores how the use of alternative materials, supply chain optimisations, and offsetting the remaining carbon footprint results in an eco-friendly drug delivery device without compromising on usability or patient safety.

More than 16 billion injections are administered worldwide every year. A significant portion of these injection devices heads straight for the landfill – shockingly, less than 10% of diabetes patients used specific containers for the disposal of their needles, syringes, and pens. For patients living with chronic diseases, injection devices are an indispensable part of their disease management routine. Instead of burdening the environment – self-care should help to preserve natural resources and contribute to minimising waste and pollution.

Corporate responsibility

To combat this issue, Ypsomed has adopted a corporate sustainability programme that embraces environment-friendly and resource-saving actions. Ypsomed is committed to achieving net-zero carbon emissions by 2030, and, to achieve this, the company is reorienting its manufacturing processes, supply chain, and self-injection device designs towards a less resource intensive, more circular mindset.

Ypsomed is embracing the three core principles proposed by the Ellen MacArthur Foundation (Cowes, UK) and others to build a positive future economy:

- Design out waste and pollution – consider waste as a design flaw and use new materials and technologies

- Keep products and materials in use – enable product and component reuse, repair, and re-manufacturing. Allow materials to be recovered so that they do not end up in landfill

- Regenerate natural systems – restore valuable nutrients to the soil and other ecosystems to enhance our natural resources.

Innovating drug delivery with YpsoMate Zero

Ypsomed’s YpsoMate autoinjector for use with prefilled 1.0 mL syringes is a state-of-the-art prefilled autoinjector that provides patients with a simple and convenient automatic two-step injection procedure, and has been chosen by Ypsomed to have its environmental impact minimised.

YpsoMate prioritises patient safety and the ability to use the device effectively. However, its single-use nature has put the prefilled autoinjector at the forefront of the global plastic challenge, and is also is used across chronic disease areas where patients regularly self-inject over a long period of time, meaning that continued YpsoMate-based self-injection leads to a considerable accumulation of waste during therapy.

A lifecycle assessment was conducted to obtain a quantitative and systematic perspective on the environmental costs of the twostep autoinjector over its entire lifecycle, including raw materials, manufacturing, and final disposal. The analysis highlighted the environmental hotspots and enabled evidence-based and data-driven design optimisations.

The analysis also provided two key insights that guided the subsequent optimisation efforts to minimise the environmental effects of the device. First, the materials used for the device components had the greatest impact on the device total carbon emissions: the polymer components, such as the device housing, the syringe holding unit, and the components used to remove the needle guard, accounted for about 60% of the total carbon emissions of the device. Second, the analysis confirmed that the packaging materials used to ship the device components either in-house or to the final assembly sites also constituted a significant environmental impact and were therefore a key priority.

The weight of the materials used to securely package the autoinjectors is more than half of the overall device weight and contributed to about 20% of the total carbon emissions. Interestingly, the lifecycle analysis showed that the transportation of raw materials was less critical for the environmental impact of the device.

The lifecycle analysis thereby provided the basis for reducing the YpsoMate carbon emissions, directing the engineering efforts towards the most pressing environmental hotspots:

- Use of alternative polymers for selected device components and packaging (e.g. device housing and packaging tray)

- Close the loop for the packaging of device components and device subassemblies (e.g. trays, pallets)

- Implement design for recycling into the development process

Several optimisation loops have resulted in a substantial reduction of the total carbon emissions. However, a state-of-the-art injection device cannot be designed in such a way that the carbon footprint is zero. With the aim of creating a fully carbon neutral prefilled autoinjector, a separate programme is needed to offset the remaining carbon footprint.

The Ahueni reforestation programme

Ypsomed invests in its own programme to substitute carbon emissions. The Ahueni reforestation programme in Kenya enables the generation of carbon emission certificates while committing to the highest industry standards. Since its launch three years ago, the programme has planted 350,000 indigenous tree species to bind carbon in the long run, create new habitats for plants and animals and proactively include local communities in the project to regenerate their ecosystem.

Enabling zero carbon emission products through collaboration

The world’s first net-zero carbon emission autoinjector paves the way towards carbon neutral combination products.

On the one hand, the insights gained from YpsoMate Zero inform the overall transition to zero carbon emission self-injection device platforms at Ypsomed. On the other hand, the YpsoMate Zero also reiterates the need to bring together the commitments of partners to achieve a net-zero carbon emission combination product.

Enabling the launch of a zero carbon footprint combination product requires the involvement and co-ordination of multiple actors along the value chain in order to adopt the principles of the circular economy and remove its barriers to adoption. The journey to zero goes beyond Ypsomed’s own operations, products, and services. To this end, the company is fostering collaborative problem solving, shaping regulatory frameworks, and promoting the circular mindset with a science-based approach. Collaboration along the value chain will help Ypsomed to enable zero carbon footprint combination products.

About Ypsomed

Ypsomed’s comprehensive drug delivery device platforms include autoinjectors for prefilled syringes in 1 mL and 2.25 mL formats, disposable pens for 3 mL and 1.5 mL cartridges, re-usable pen injectors, ready-to-use prefilled wearable patch injectors and connected devices and digital services. Unique click-on needles and infusion sets complement the broad product portfolio of self-injection systems.

With over 30 years of experience and pioneering spirit in the development and manufacturing of innovative injection systems, Ypsomed is well equipped to tackle one of the most pressing challenges of our time: the reduction of carbon emissions. Ypsomed anticipates the future needs of patients, pharmaceutical customers, payers, and healthcare professionals, striving with its product solutions to change patients’ lives and minimise environmental impact.

Ypsomed is ISO 13485 certified, and all processes comply with design control and cGMP guidelines with operational QA/QC experts on site at each location. Ypsomed’s US FDA-registered manufacturing facilities are regularly inspected by both pharma customers and regulatory agencies to supply devices for global markets including the US, Europe, Japan, China, and India.

Get in touch with us to join our journey to zero: zero@ypsomed.com.